5-Axis Lathe Turning & Milling

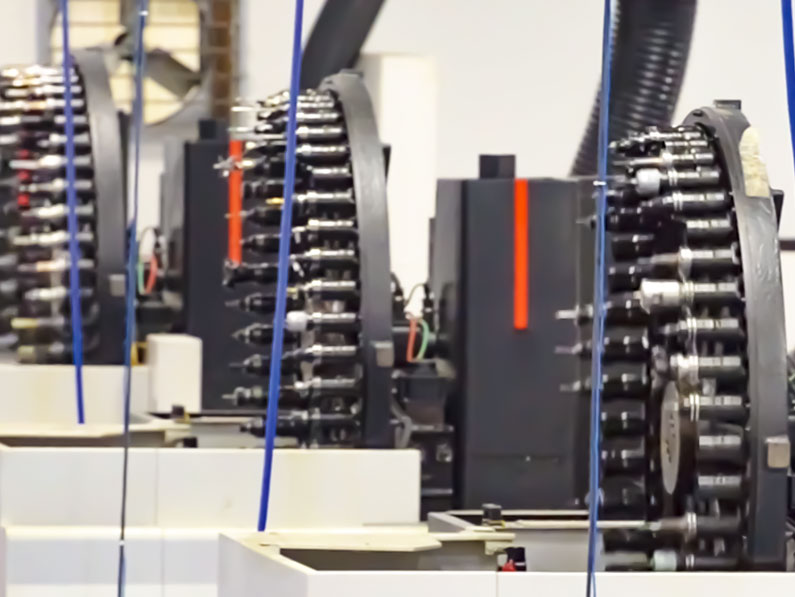

Lathe Turning & Milling at CED Services expands the manufacturing capabilities associated with single spindle machines. Our turn/mill system goes beyond the simple fixed spindle process, offering multi-axis tooling functions that let us produce complex parts through both milling and turning in just one machining cycle.

Our milling/turning services include the expansive capabilities of the Mazak Integrex I—a multi-tasking machine that turns, mills, taps, and drills while delivering superior 5-axis contouring. The system coordinates multiple large-tool magazines, counter spindles, and multi-turret cutting to provide single-machine efficiency to reduce cycle times and deliver precise tolerances and part finishes. Elaborate components we machine using the turn/mill process are used in the Aerospace, Automotive, Medical and Defense industries.

CED Turning & Milling Equipment:

- 2 Mazak Integrex I, 200 Series

5 Axis, 110 Position Tool Changer W/Gantry - 2 Mazak Multiplex W-200Y

with loader - 1 Mazak Integrex I, 200 Series,

5 Axis, 110 Position Tool Changer - 1 Mazak Integrex I 400 Series,

5 Axis, 110 Position Tool Changer

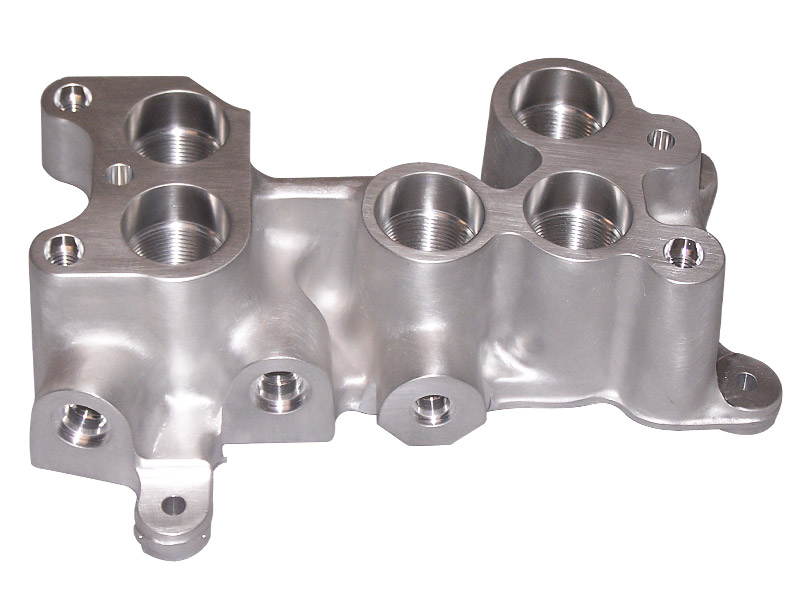

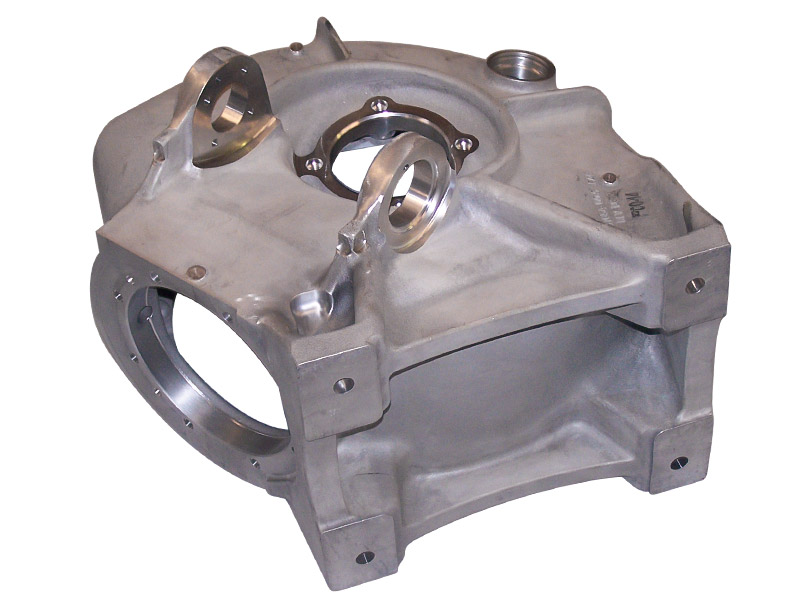

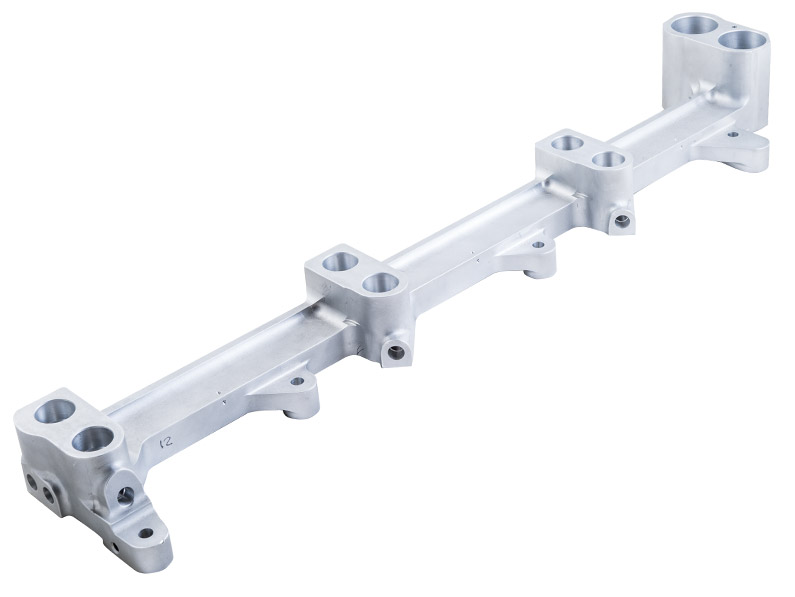

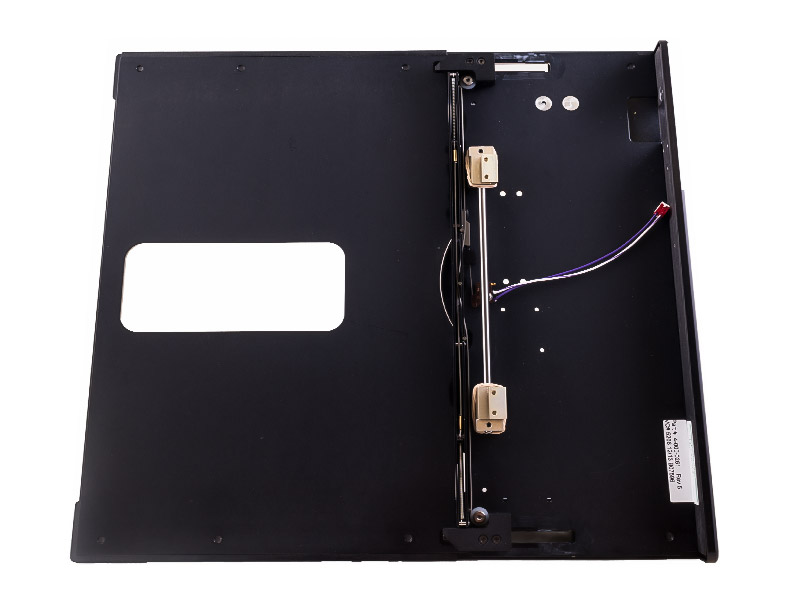

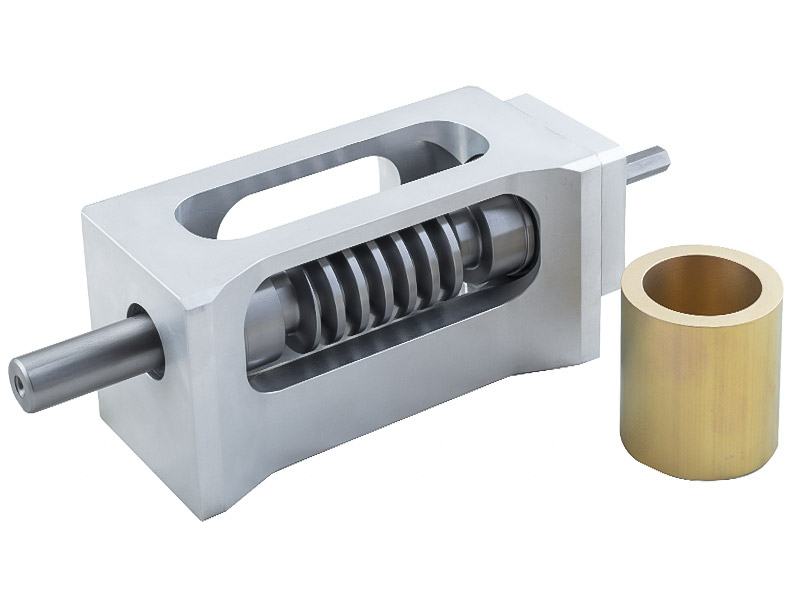

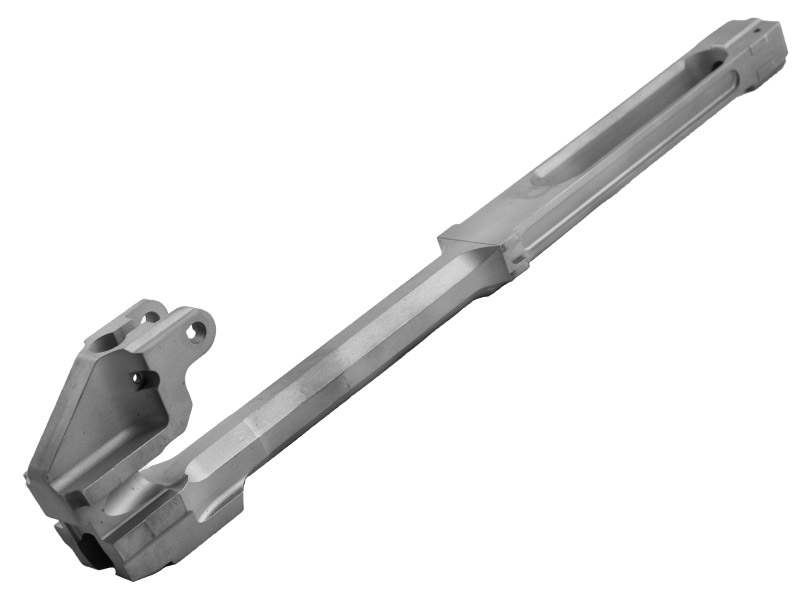

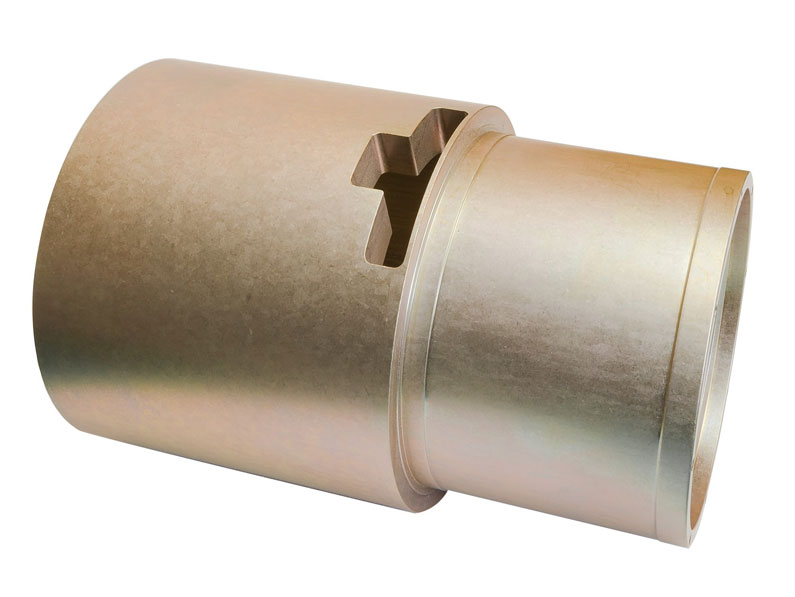

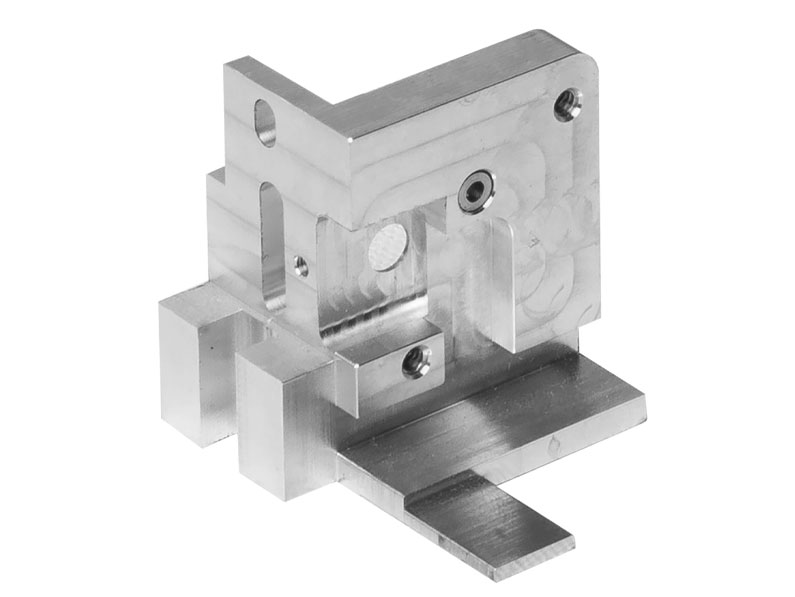

CED Machined Parts and Components Gallery

(click images to enlarge)

Contact CED Services

Have a question? Need a quote?

Call or email us today!

203-828-6528

6 Reasons to consider CED :

1. Diverse Capabilities: Our advanced equipment and AS9100D/ISO9001:2015 Certificate ensure specified-precion for parts and subassemblies used in the most demanding industries.

2. Customer Dedication: Experienced professionals focused on your part program success.

3. Lower Cost: Consistently higher-quality parts—machined for less.

4. Convenient Location: Nestled in Oxford, Connecticut, USA — only 1 mile from Oxford Airport.

5. Vendor Upgrade Program: Our 3-step program eliminates vendor-switching nightmares.

6. Reputation: Our world-class precision and service have earned praise and trust from our customers...

Read what CED clients say:

“We enjoy our relationship with CED for several reasons namely, that they have the expertise that our products require and the equipment that can efficiently produce it. Their decision making people are skilled in their areas of expertise. This, plus their attitude of "what can we do to help you" is a combination that has served us well.”

Tom Chiaramonte, Engineer | Triumph Actuation Systems

“CED has consistently proven they can produce top quality fabrications. The staff at CED offers outstanding Engineering support. The cycle time associated with design, prototyping and assembly verification is greatly reduced due to CED's commitment to quality and service.”

Tom Farbizio , Engineer | Hologic Inc.

Consulting, Engineering & Development Services, Inc.

3 Fox Hollow Road,

Oxford, CT 06478