Quality Assurance for Complex Machined Parts

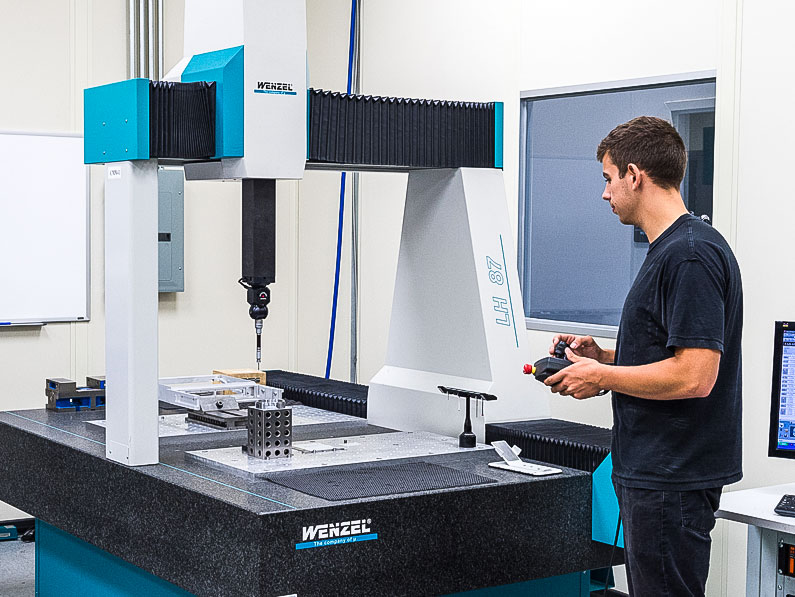

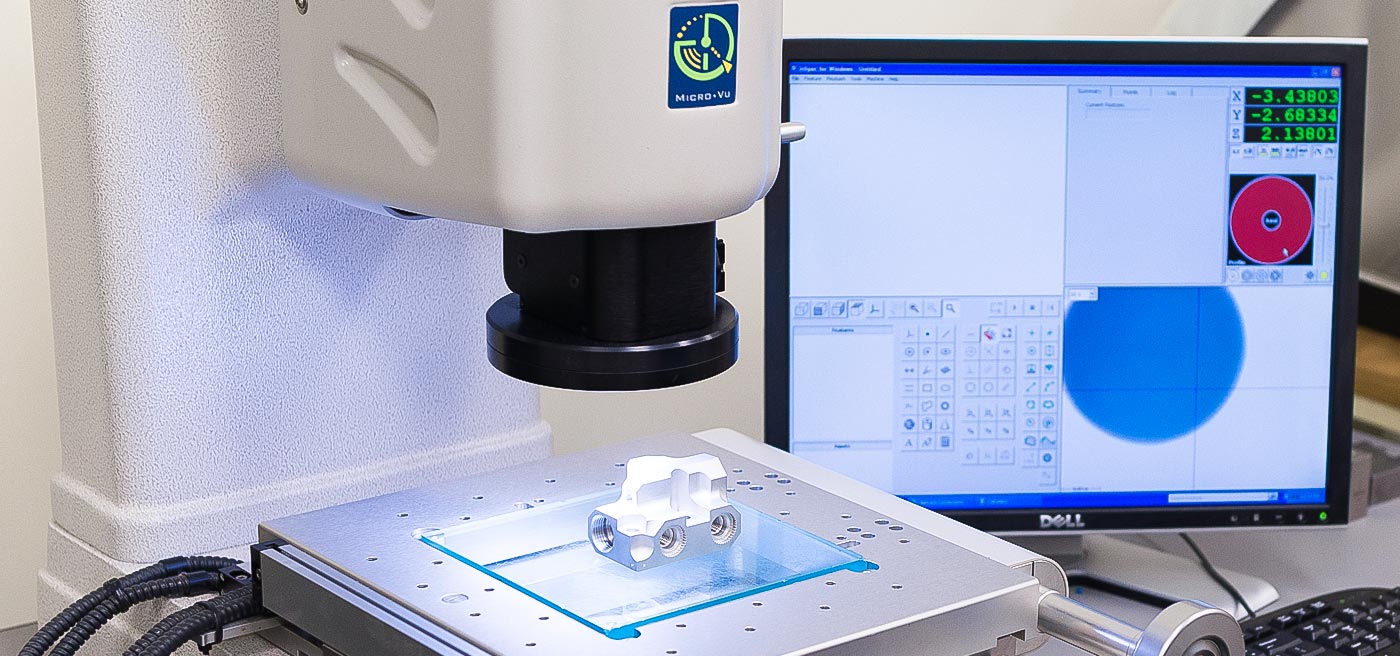

CED’s dedicated Quality Assurance Lab monitors and details every step on the part manufacturing cycle

Quality Assurance for machined metal parts has become a global concern. We have responded by making a systematic Quality Management Program part of every part project we undertake.

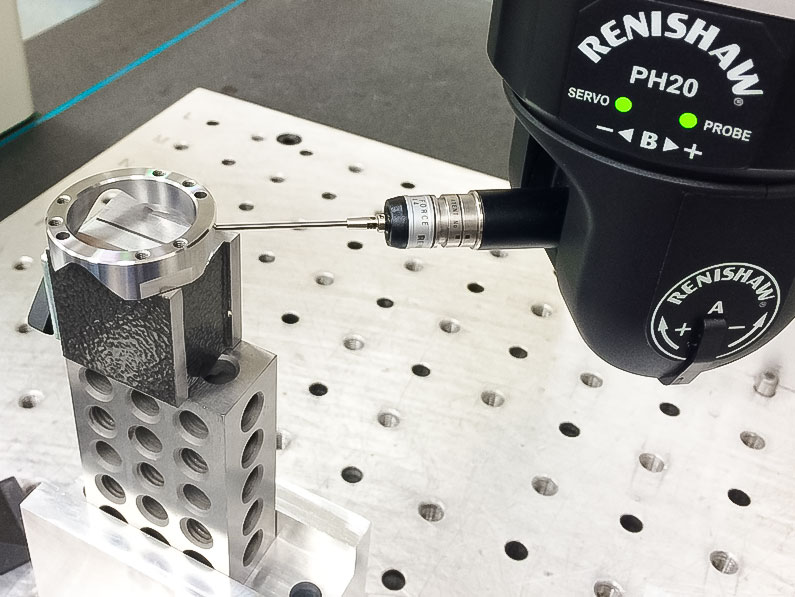

Our dedicated Quality Assurance Lab contains today’s most advanced, measuring, inspection, evaluation, and documentation technologies. Beginning with the very first part machined — and throughout the machining cycle — product quality and tolerances are strictly monitored and documented with lock step precision. We accept no less that 100% accuracy and consistency for every part leaving our plant.

At CED, we’ve proven that implementing and maintaining a regimented QA process actually saves time and resources in the long run by reducing or eliminating waste, and improving delivery schedules for tolerance-critical parts.

A partial equipment list of the inspection technology we use includes:

- Wenzel X Orbit WPH 20 Head X 35.5″ Y 59″ Z 27.6″

- Wenzel LH87 CNC CMM with Tool Changer X31.5 Y59.0 Z27.5

- 1-Mitutoyo Surftest SJ-410

- Horizon Premium Analogique HPA 500 Horizontal Measuring and Calibration System

- Brown & Sharpe CNC CMM X24 Y26 Z19 with Renishaw PH20 Indexable Head & Probe System

- Video Microview Microscope No. v 260 .0001 Increments

- Horizon Premium Supre Micrometer HPA 500 Horizontal Measuring and

- Calibration System

- Fowler Trimos 600+

- Fowler Trimos Altia

- Hawk Eye Luxxor Video Precision Bore Scope

- Hawk Eye Pro Superslim Bore Scope

- 12 Surface Plates 12″x18″

- 6 Surface Plates 24″x48″

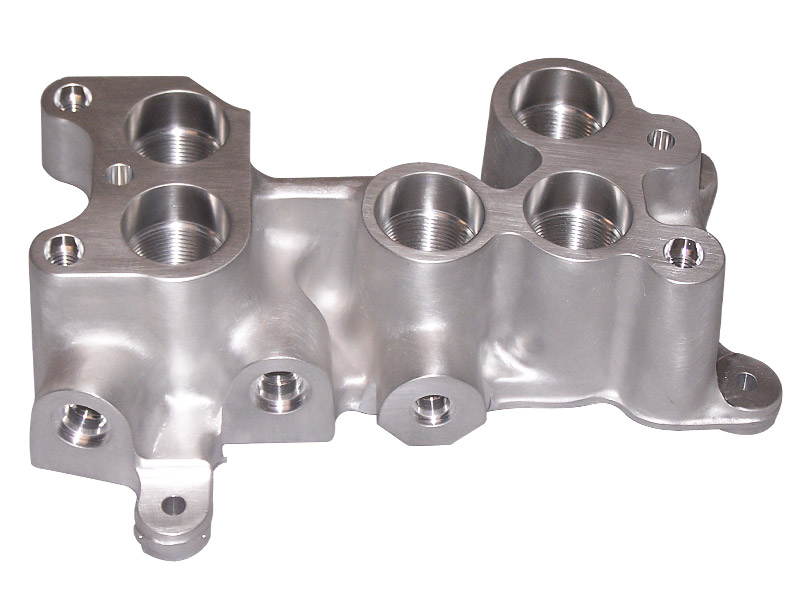

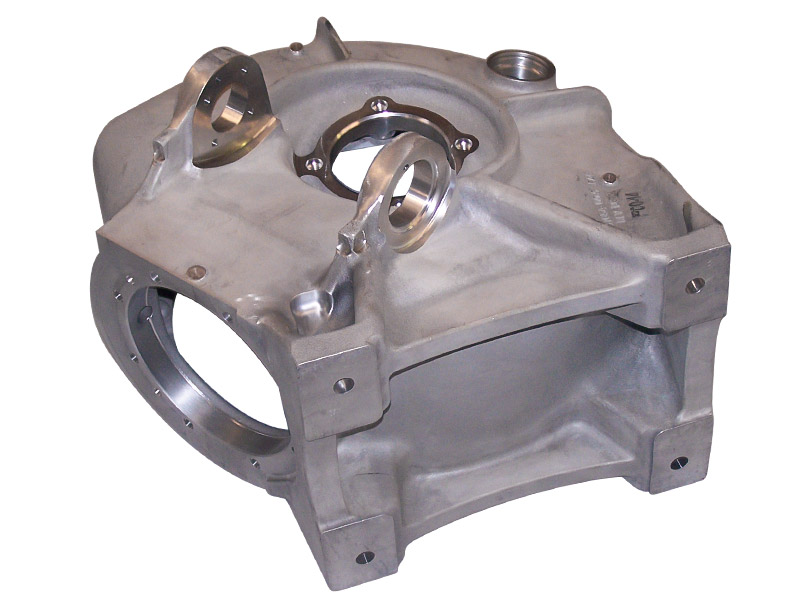

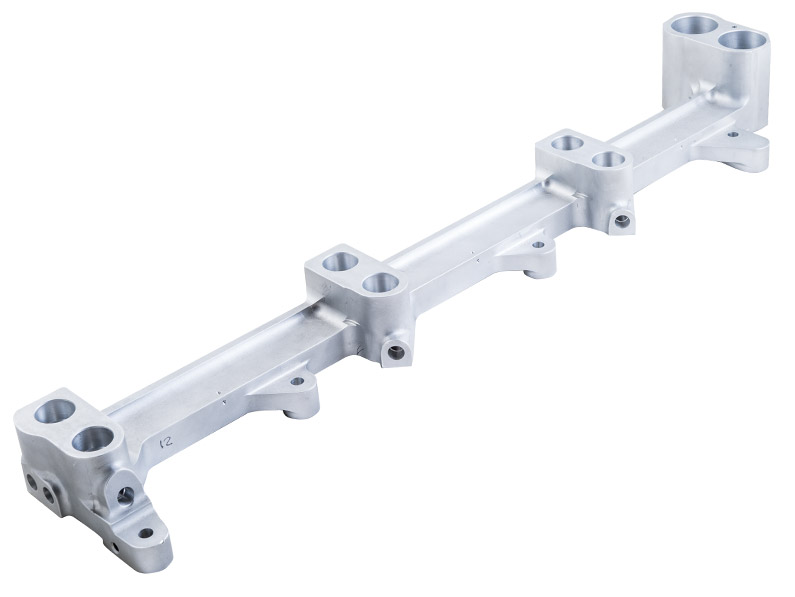

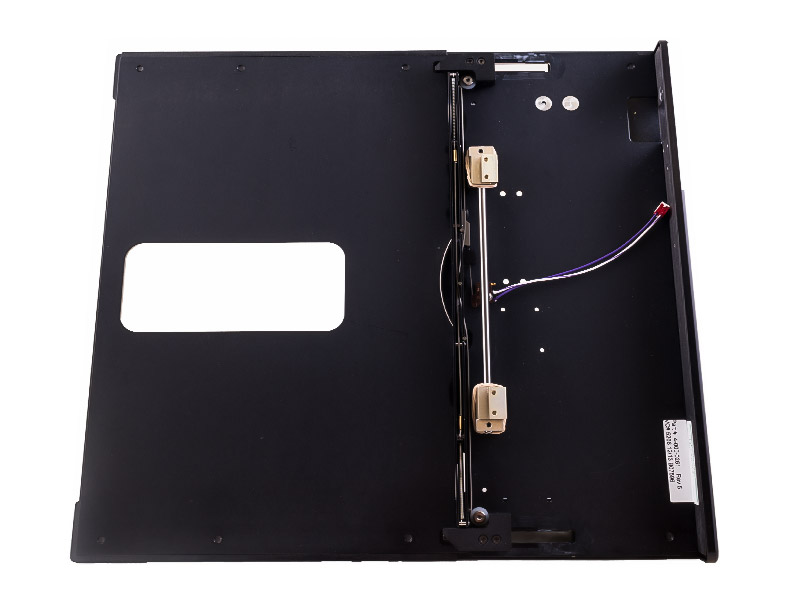

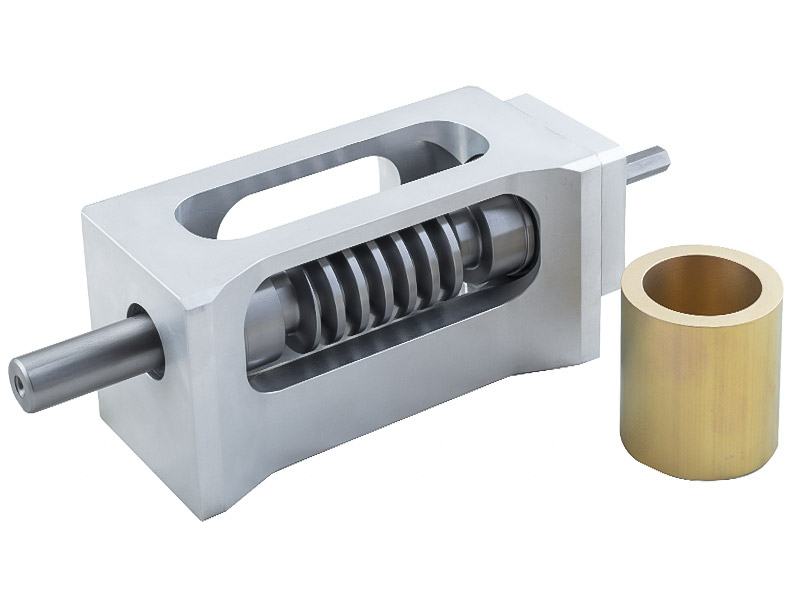

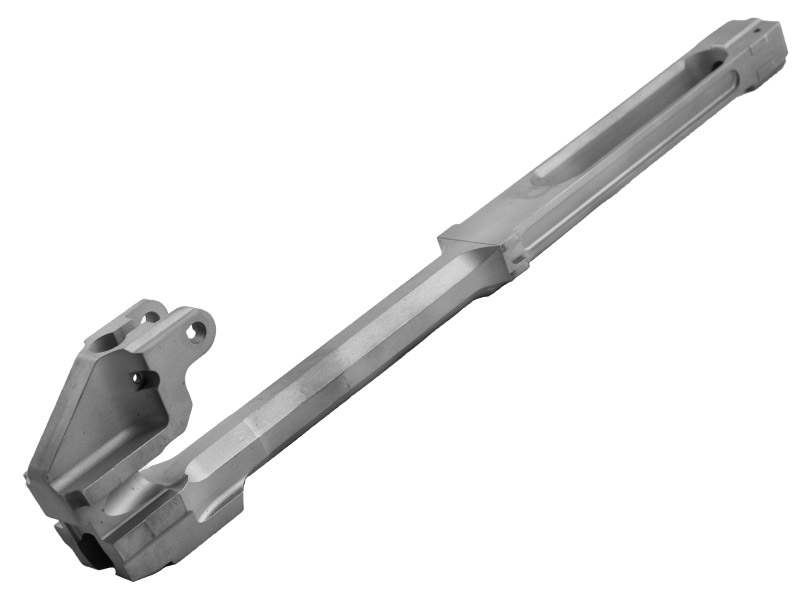

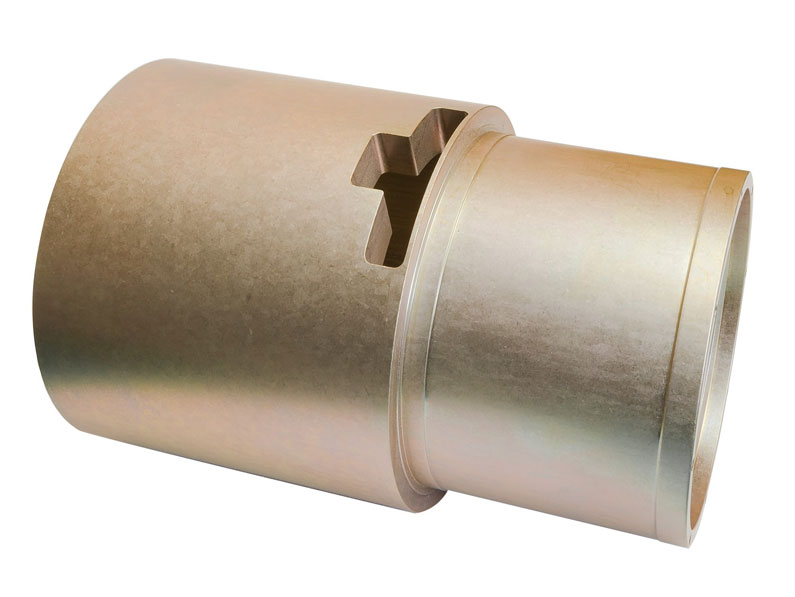

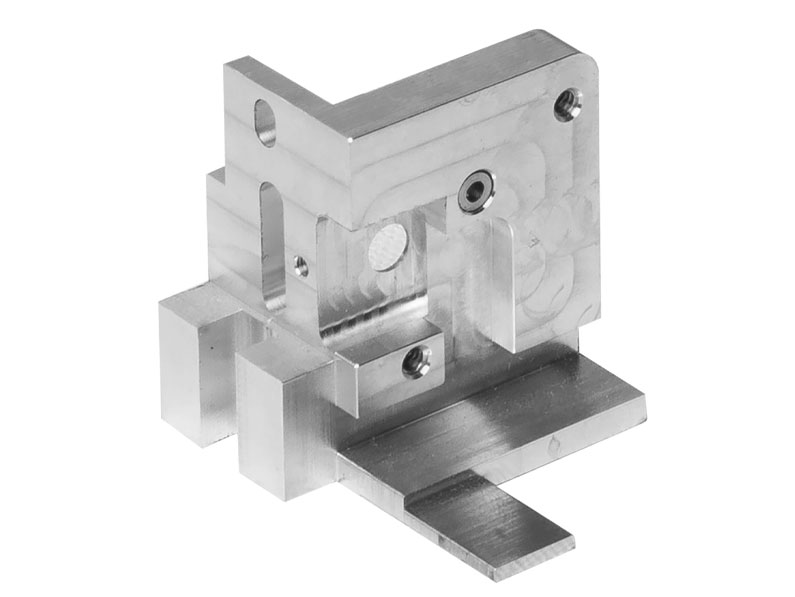

CED Machined Parts and Components Gallery

(click images to enlarge)

Contact CED Services

Have a question? Need a quote?

Call or email us today!

203-828-6528

6 Reasons to consider CED :

1. Diverse Capabilities: Our advanced equipment and AS9100D/ISO9001:2015 Certificate ensure specified-precion for parts and subassemblies used in the most demanding industries.

2. Customer Dedication: Experienced professionals focused on your part program success.

3. Lower Cost: Consistently higher-quality parts—machined for less.

4. Convenient Location: Nestled in Oxford, Connecticut, USA — only 1 mile from Oxford Airport.

5. Vendor Upgrade Program: Our 3-step program eliminates vendor-switching nightmares.

6. Reputation: Our world-class precision and service have earned praise and trust from our customers...

Read what CED clients say:

“We enjoy our relationship with CED for several reasons namely, that they have the expertise that our products require and the equipment that can efficiently produce it. Their decision making people are skilled in their areas of expertise. This, plus their attitude of "what can we do to help you" is a combination that has served us well.”

Tom Chiaramonte, Engineer | Triumph Actuation Systems

“CED has consistently proven they can produce top quality fabrications. The staff at CED offers outstanding Engineering support. The cycle time associated with design, prototyping and assembly verification is greatly reduced due to CED's commitment to quality and service.”

Tom Farbizio , Engineer | Hologic Inc.

Consulting, Engineering & Development Services, Inc.

3 Fox Hollow Road,

Oxford, CT 06478